In manufacturing and product development, finding efficient and cost-effective techniques is paramount. Among the myriad of producing strategies, vacuum forming sticks out as a versatile and quite useful technique. This article will provide a comprehensive guide on vacuum forming service and highlight its benefits for various industries.

What Is Vacuum Forming?

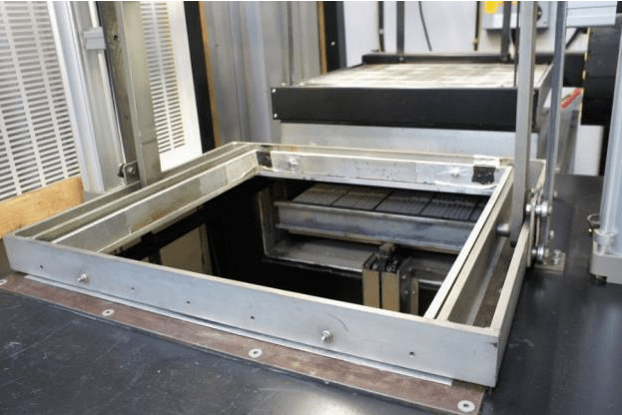

Vacuum forming is a manufacturing technique that involves heating a plastic sheet until it becomes pliable. Then, stretch it over a mold and use the vacuum to suck out the air, as a consequence developing a preferred shape.

This approach is helpful in industries ranging from automobile and aerospace to packaging and patron items. The process is simple but notably flexible, making it appropriate for each prototyping and huge-scale production.

Vacuum Forming in China

Vacuum forming China has emerged as a widespread participant in the international manufacturing landscape. With its superior era, professional staff, and competitive pricing, China is a compelling destination for vacuum-forming offerings. Companies seeking cost-powerful answers and fast turnaround times regularly flip to Chinese manufacturers for their needs.

The Vacuum Forming Process

Its method starts with choosing the precise thermoplastic sheet, along with acrylic, polystyrene, or ABS. The selected fabric is then clamped into the area and heated till it reaches the preferred temperature for forming.

Once heated, the sheet is draped over a mildew and a vacuum is applied, inflicting the plastic to conform to the form of the mold. After cooling, the fashioned plastic is trimmed to size, resulting in the last product.

Benefits of Vacuum Forming Service

- Cost-Effectiveness: One of the primary advantages of vacuum forming is its cost-effectiveness, particularly for low to medium-volume production runs. The simplicity of the technique and the potential to reuse molds make it a cost-effective choice for producing prototypes, custom components, and additives.

- Versatility: Another great benefit is its versatility. The system can accommodate a variety of shapes, sizes, and complexities, considering the introduction of complicated designs and distinct textures. Additionally, numerous materials can be used, presenting flexibility in aesthetics, sturdiness, and overall performance.

- Rapid Prototyping: It offers a brief and efficient solution For product improvement and prototyping purposes. With minimum setup time and the capacity to provide prototypes in a count of hours, designers and engineers can iterate and test their designs rapidly, accelerating the improvement procedure.

- Scalability: While it is appropriate for small-scale manufacturing runs, it is also scalable for large-quantity manufacturing. With improvements in technology and automation, vacuum forming procedures are optimized for high-speed manufacturing without compromising on pleasant or precision.

- Quality and Consistency: Despite its simplicity, it gives brilliant greatness and consistency inside the completed merchandise. With particular control over heating, cooling, and vacuum pressure, producers can attain tight tolerances and uniformity throughout a couple of components, ensuring reliability and performance.

Concluding Lines:

Vacuum forming is a versatile and cost-effective manufacturing technique that offers several benefits for numerous industries. From rapid prototyping to huge-scale production, thermoforming vacuum forming provides quality, consistency, and scalability. With its capacity to accommodate various shapes, substances, and volumes, it remains a desired choice for manufacturers globally.