The process of waterproofing is an essential step in the construction and maintenance processes that aims to prevent water and moisture from penetrating buildings and other structures.

The built environment, including private residences and commercial structures, must be waterproofed in order to safeguard its longevity, structural integrity, and aesthetic appeal.

This blog will delve into the complexity of the process of waterproofing, studying its importance as well as its procedures, materials, and benefits.

The Value of Waterproofing

Water is one of the most damaging elements that nature has to offer, and the fact that water may penetrate structures can lead to a wide variety of complications. The presence of moisture inside of a building may result in the growth of mould, the corrosion of steel reinforcements, the degradation of concrete, and even the compromise of the structure’s structural integrity.

When a building is waterproofed properly, it is protected not just from precipitation, but also from other forms of moisture, such as ground moisture, humidity, and condensation. Waterproofing protects against all of these types of moisture.

Various Methods of Waterproofing

When it comes to construction and maintenance, waterproofing may be accomplished via a variety of methods, each of which can be tailored to meet the specific requirements of a given circumstance. The following are some of the most often used methods:

1. Surface Waterproofing: This method involves applying a protective coating or membrane to the outside surface of a building in order to stop water from entering the building. Coatings made of bitumen, acrylic, polyurethane, and elastomeric polymers are some examples of surface waterproofing materials.

2. “Integral Waterproofing” refers to the practice of incorporating waterproofing chemicals into the concrete while it is still in the building phase. These compounds have the effect of contracting the capillary holes in the concrete, which in turn reduces the amount of water that can move through the pores.

3. The Cavity Drainage method: This method involves the creation of a space or cavity between the outside and inner walls of the building. This space allows water to enter the building while simultaneously directing the water away from the building through drainage outlets. This method is often used in the construction of subterranean structures.

4. “Injection Waterproofing”: Cracks and seams in the concrete structure are vulnerable points where water may enter the structure. The process of injecting specific materials into cracks in order to seal them and prevent water from entering is known as injection waterproofing.

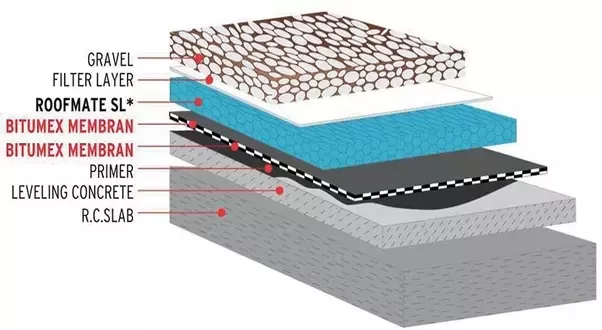

5. Membrane Waterproofing: This technique involves the use of membranes made of materials such as PVC, TPO, or EPDM in order to create a barrier that prevents water from penetrating the structure. These membranes might be useful in a variety of settings, including basements, cellars, and other sensitive areas.

6. Sheet Membrane Waterproofing: Adhesives or heat-welding methods are used to affix pre-manufactured sheets of waterproofing material to surfaces. Sheet membrane waterproofing is a kind of sheet membrane waterproofing. This method results in a water barrier that is both smooth and effective.

Supplies for preventing water infiltration

There is a wide range of material that may be used for waterproofing, and each of these materials has its own specific set of attributes and applications:

1. Bituminous Membranes: Bitumen is a sticky and viscous substance that may be linked with polymers to increase its performance. Bituminous membranes are used in a variety of applications. Bituminous membranes are commonly used in the process of waterproofing roofs.

2. Polyurethane: Coatings made of polyurethane are versatile and may be applied to a wide range of surfaces, including concrete, metal, and wood. They are very resilient as well as versatile.

3. The third phase is the application of cementitious waterproofing. These cement-based coatings, once applied, provide a sturdy barrier. They are capable of withstanding hydrostatic pressure and are often used for the purpose of interior waterproofing.

4. Liquid Applied Membranes: These coatings are applied in the form of a liquid and then allowed to cure in order to generate a membrane that is both seamless and flexible. They are an ideal choice for usage on uneven surfaces and may be installed on roofs, balconies, and patios.

5. Crystalline Waterproofing: This one-of-a-kind strategy makes use of crystalline chemicals that react with moisture to form insoluble crystals inside the concrete. This process is known as a “crystalline waterproofing.” These crystals provide long-term waterproofing by obstructing the paths that water would normally take.

The Benefits Brought by Proper Waterproofing

1. An extended lifespan: Waterproofing done correctly has been shown to significantly improve the lifetime of a structure by lowering the amount of damage caused by moisture.

2. Structural Integrity: Waterproofing maintains the structural integrity of a building by avoiding water entry and minimising the likelihood of fractures, corrosion, and the degradation of the structure’s materials.

3. Health and Safety: Waterproofing helps to avoid the growth of mould, which may be harmful to the quality of the air within a building and to the occupants’ health.

4. Cost Savings: Making an investment in waterproofing early on may save a significant amount of money later on when it comes to repairing water damage and addressing structural issues.

5. Waterproofing may help conserve energy by reducing the amount of heat that is lost and the amount of work that is done by heating, ventilation, and air conditioning (HVAC) systems.

Waterproofing prevents water and moisture damage in construction and building maintenance. Waterproofing protects buildings from weather and ensures a healthy, secure living space. Therefore, Waterproofing in a building, whether residential or commercial, cannot be stressed enough.