Integrated circuit packaging significantly affects the reliability, efficiency, as well as effectiveness of electronic component production. The DIP and the SOP are two popular packaging designs. In this blog, we will explore the distinctions between DIP and SOP packages:

DIP

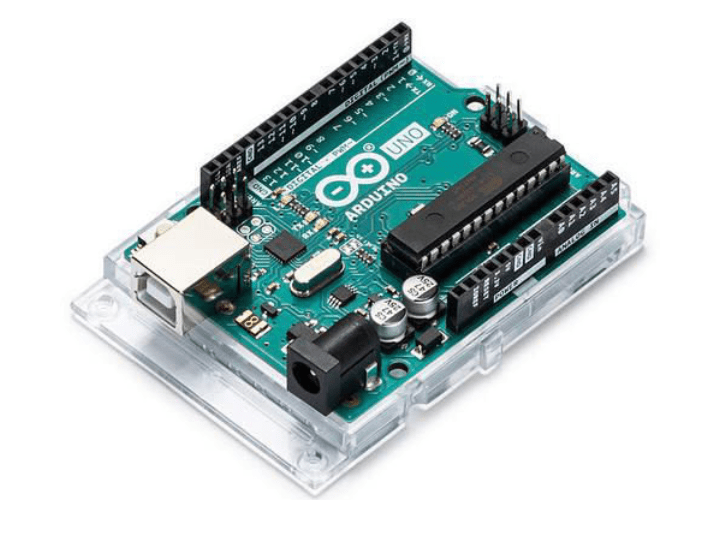

DIP meaning Dual In-line Package, it is a traditional design for packaging with two parallel rows of connecting pins on opposite sides of the box. Because these pins emerge from the package vertically, inserting them into a PCB connection is made simpler. Through-hole technology, in which the leads are soldered on one side after being introduced through holes in the PCB, is frequently linked to DIP packaging.

SOP

A more contemporary and room-efficient packaging design is the Small Outline Package, or SOP. With gull-wing or J-lead surface-mount leads that rise from the sides of the package, SOPs have a smaller form factor. Unlike DIP, SOPs are designed for surface-mount technology, where components are mounted directly onto the surface of the PCB.

Physical Characteristics

DIP Package

- Shape: Rectangular with two rows of pins.

- Leads: Through-hole leads extending vertically.

- Mounting: Requires a socket on the PCB for insertion.

- Size: Generally larger compared to SOPs.

- Orientation: Typically mounted perpendicular to the PCB.

SOP Package

- Shape: Rectangular or square with surface-mount leads.

- Leads: Gull-wing or J-lead configuration for surface mounting.

- Mounting: Directly mounted onto the surface of the PCB.

- Size: Compact, contributing to space efficiency.

- Orientation: Parallel to the PCB surface.

Advantages and Disadvantages

Advantages of DIP Packages:

- Versatility: DIP packages are adaptable and simple to test and replace by plugging them into sockets.

- Prototyping simplicity: Frequently employed because of their accessibility and simplicity of handling.

- Fit for through-hole assembly procedures: through-hole assembly.

Disadvantages of DIP Packages:

- Space Inefficiency: DIP packages are generally larger, making them less space-efficient in modern, compact electronic devices.

- Limited Pin Count: The size constraints of DIP packages can limit the number of pins available for connections.

Advantages of SOP Packages:

- Space Efficiency: SOP packages are compact, allowing for high-density component placement on PCBs.

- Surface Mounting: Designed for surface-mount technology, contributing to efficient manufacturing processes.

- Suitable for Modern Devices: Ideal for contemporary electronic devices with a focus on miniaturization.

Disadvantages of SOP Packages:

- Less Versatility: SOP packages are less versatile for prototyping and testing compared to DIP-packages.

- Surface Mounting Challenges: Surface mounting may pose challenges for some manufacturing processes.

Evolution and Industry Trends

DIP Packages:

- Legacy Use: While DIP packages are still found in certain applications, they are considered legacy components in the context of modern electronics.

- Replacement with SOP: In many cases, DIP packages have been replaced by SOPs in the design of new electronic devices.

SOP Packages:

- Commonplace in current Electronics: Because SOP packages are compatible with surface-mount technology and take up little space, they are commonly seen in current electronic devices.

- Continuous Innovation: SOP technology is always evolving, which helps to reduce size and boost efficiency.

Cost Considerations

DIP Package Costs:

- Lower Initial Costs: DIP packages may have lower initial manufacturing costs, making them suitable for cost-sensitive applications.

- Higher Long-Term Costs: In the long term, the larger size of DIP components may contribute to increased system costs.

SOP Package Costs:

- Higher Initial Costs: SOP packages may have higher initial manufacturing costs due to advanced manufacturing processes and materials.

- Lower Long-Term Costs: The space efficiency of SOP components often leads to cost savings in terms of board space and overall system costs.

In conclusion, it is critical for electronics designers, producers, and individuals to comprehend the distinctions between DIP and SOP packaging. The decision between these two package designs is affected by a number of variables, including industry trends, production procedures, and application needs. As technology advances, SOP packages are likely to play an increasingly prominent role in shaping the landscape of electronic components and systems.