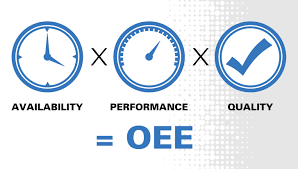

Overall Equipment Effectiveness, also called OEE for short, measures three core qualities of your manufacturing process: Availability, Performance and Quality.

Availability takes into consideration instances like unplanned and planned stops – meaning those instances where you’re not making the most use out of your planned production time. Performance, on the other hand, looks at slow cycles and small stops – meaning those periods where you’re not running as quickly as possible for whatever reason.

Quality looks at defects in your manufacturing process – accounting for parts that need to be reworked, regardless of the reason. An OEE score of 100% means that you’re only producing parts with no stop time, as quickly as possible, with as few quality issues to speak of.

While this may sound straightforward, it’s also entirely possible to misinterpret an OEE score to your detriment. In fact, there are a few OEE mistakes that many businesses make that you would do well to avoid at all costs.

Understanding OEE: Your Overview

One of the biggest OEE mistakes that a lot of organizations make involves comparing the scores of different processes without considering the larger contexts between them.

Yes, it’s true that OEE can be a viable way to compare the productivity of one production line – or even a different facility – to another. But if you don’t make an effort to truly understand the differing conditions between them, you won’t be able to draw the insight that you assume you will.

If you’re going to be using OEE to compare anything at all, you really need to do so using A) equivalent machines that are B) being employed to produce the same product in the same way. Anything else really does create a “comparing apples to oranges” situation – which isn’t giving you nearly as much analysis as you think it is.

Another significant mistake that a lot of people make when it comes to OEE involves choosing a very short time period for which to analyze. Yes, it’s technically possible to get an OEE score after looking at a single shift or even a single day in your manufacturing process – but again, this really isn’t telling you as much as you think it is.

Truly, you cannot gather an appropriate amount of data in such a short amount of time. In a condensed time period, single events of downtime (for just one example) will weigh down your score far too much.

For the best results, you need to be calculating OEE over much longer periods of time – think weeks or even months. While it’s true that this won’t give you the instant gratification you might be after, it will still properly account for productivity peaks and valleys that you may be experience. At the end of it all, you’ll be left with the data you need to truly understand the situation that you’re working with – which in and of itself is the most important benefit of OEE of all.